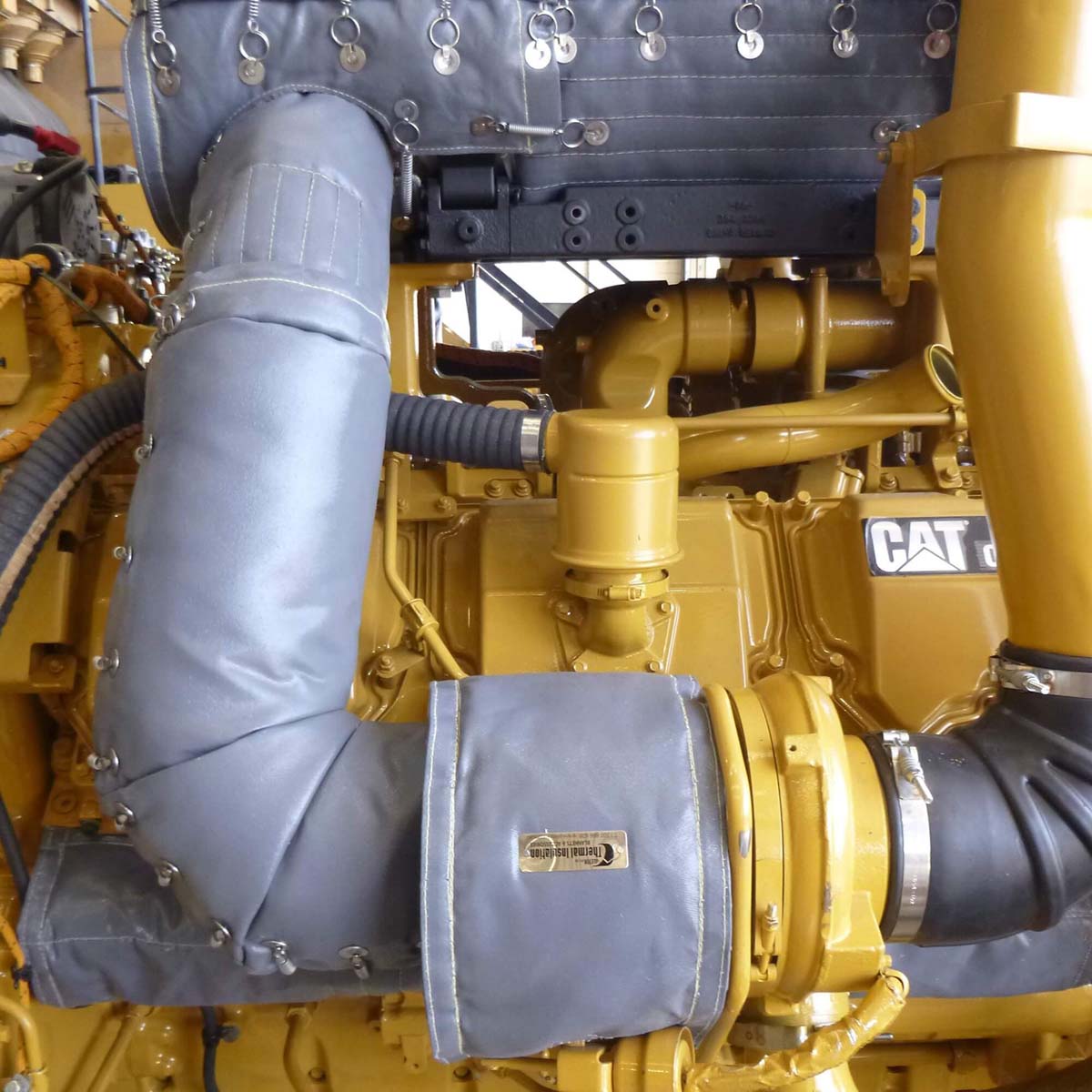

Protect your Caterpillar machines from fire with Aletek blanket kits. We cover many assets, including dozers, excavators, and haul trucks.

Mining Exhaust Lagging Kits

Is your fleet protected? Our innovative four-layer thermal blankets help prevent engine fires. You can order exhaust lagging as a complete kit for new assets or as parts groups for engine rebuilds.

Support and resources for lagging installation

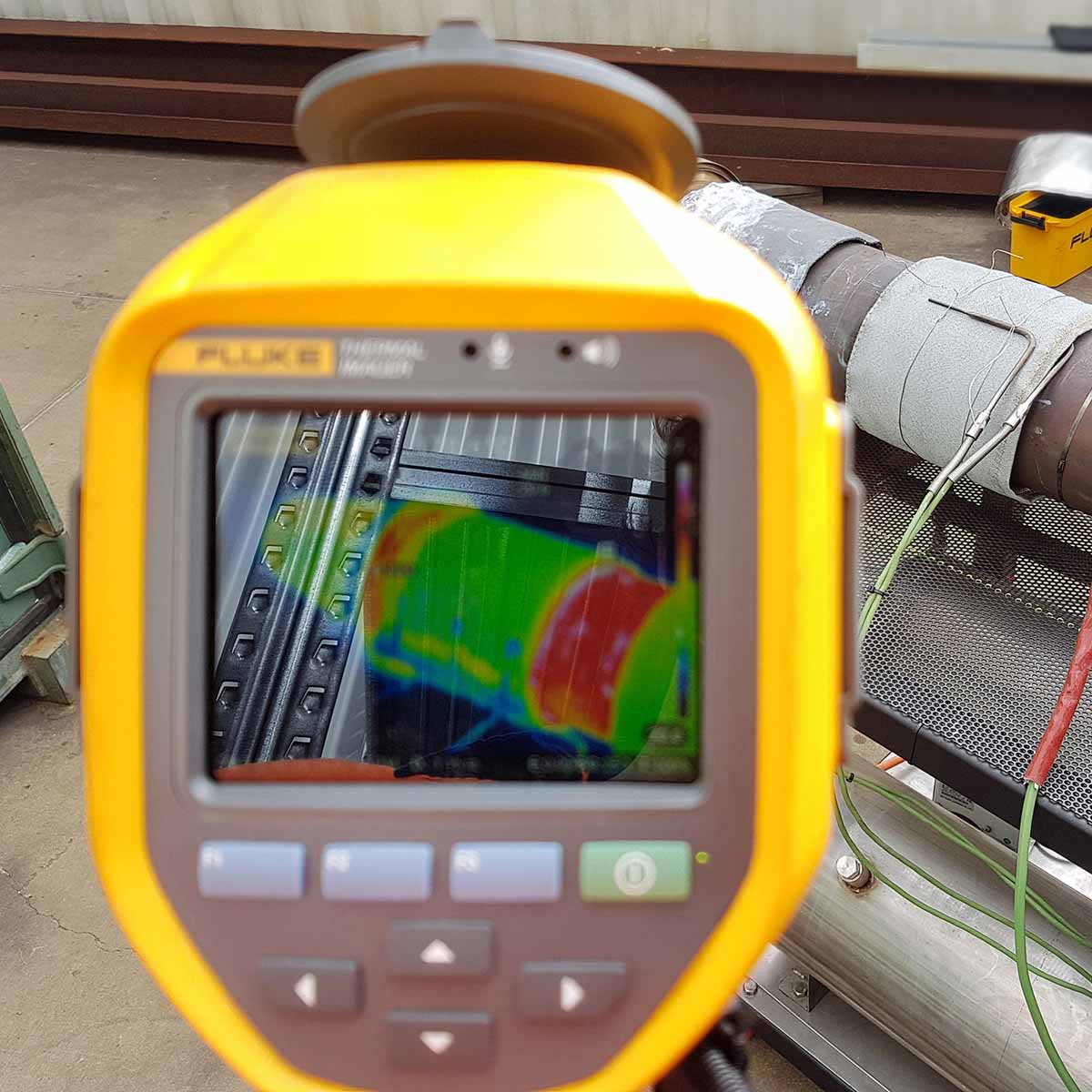

Thermal imaging and assessment

On-site fleet audits for exhausts and lagging

Training for maintenance crews

Exhaust blankets safeguard your mining fleet

-

Comply with safety standards and mitigate fires

-

Keep surface temperatures below fuel ignition points

-

Protect maintenance crews from extreme burns

-

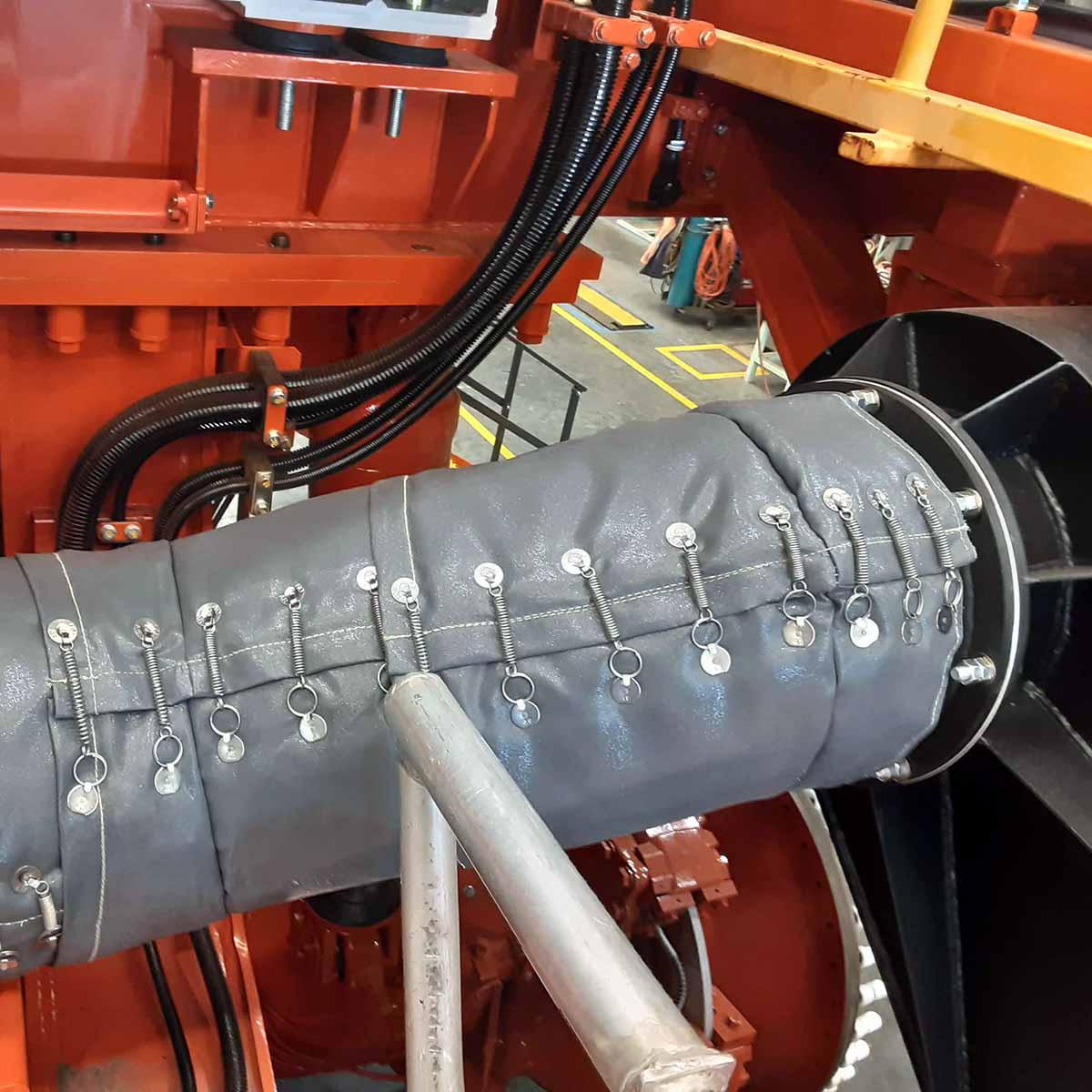

Our mining exhaust lagging is easy to install and remove

-

Fits your equipment like a glove

-

Shield heat-sensitive components from hazards (eg. high-voltage lines)

Shielding extreme-heated engine and exhaust parts with thermal insulation blankets is highly recommended. Using thermal blankets in engine bays creates a controlled barrier between fire hazards and superheated parts. Our asset-specific exhaust lagging kits can help safeguard your mobile equipment in compliance with AS 5062:2016 Standards and the MDG 15 Guideline.

Exhaust blankets can help prevent engine fires

Thermal insulation blankets create a physical barrier between superheated engine parts and flammable hazards. To prevent engine fires, cover these components with thermal blankets. You can think of blankets as your fleet’s PPE (Personal Protective Equipment).

What makes our thermal blankets better?

We tailor our blanket designs to suit each machine and fit snugly like a glove. Aletek blanket installation and removal is easy, making them popular with maintenance crews. Ditch the itch! Compared to competitors’ e-glass products, Aletek’s exhaust lagging has minimal itch.

A winning blanket layer combination

Material selection is one of our secret weapons, with the following four strategic layers:

- Silicone-coated outer

This protective layer consists of fibre-reinforced silicon that has been temperature treated on both sides. It provides strength, temperature resistance, and flexibility while resisting oil absorption. - Silica insulation

A high-performance insulating layer that dissipates temperatures up to 1700°C. These properties allow blankets to last longer and support maintenance activities without the ‘e-glass itch’. - Silica cloth

A cloth layer protects the heat-dissipating silica from dirt, oil, and contaminants. The cloth can withstand temperatures above 1000°C. - Stainless steel mesh

An inner-facing mesh reinforces the blankets and moulds to match engine components. This steel is highly resistant to corrosion, extreme temperatures, and wearing.

Superheated engine components exposed

Manifold blankets

Under full load, engine manifolds can reach 450°C. These temperatures exceed oil and fluid ignition temperatures. Our blankets reduce hot spots and prevent flammable liquids from infiltrating.

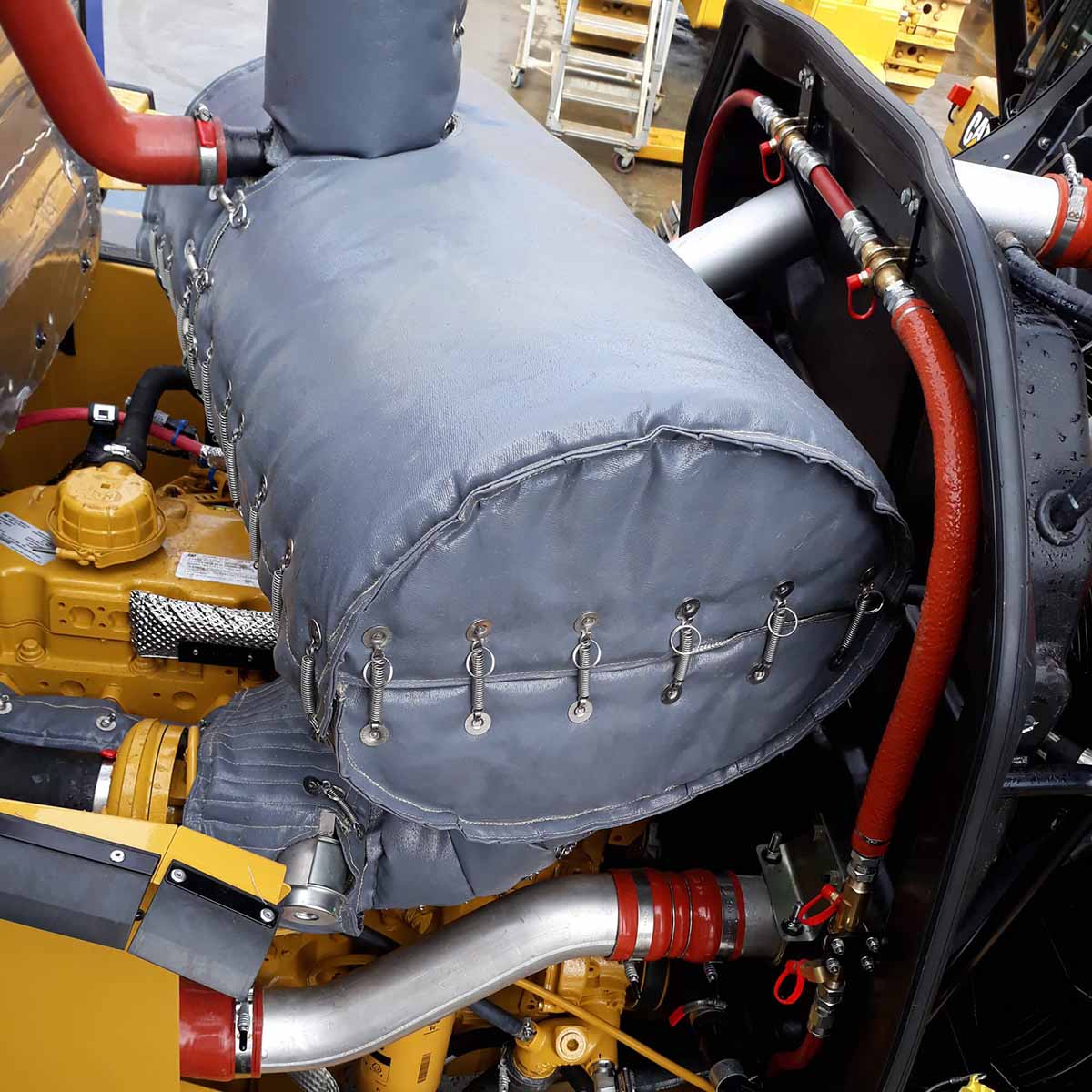

Turbo blankets

Turbos operate at extreme temperatures. Fuel leaks or ruptured hoses pose a high fire risk. Aletek turbo covers provide optimal shielding and facilitate access to fuel lines and inspection ports.

Engine pipe blankets for proximity risks

Use engine pipe blankets at locations that exceed fuel flashpoints. Typical zones include pipes in and around engine bays, junctions, and immediate hazards like grease pumps. Likewise, shielding pipes near high-voltage cables protects them from superheated exhausts.

Blankets for radiant heat concerns

Blankets can control radiant heat. For instance, mufflers can cause excessive heat inside the driver’s cab, which is unsafe to touch. In this case, add blankets to the muffler to solve this problem.

With the help of our skilled team, we manufacture our thermal blankets using lean manufacturing techniques. We produce our blankets from the finest raw materials for ultimate fleet protection.

Exhaust blanket packages and kits

Complete packages or group-based kits

Aletek blankets are available as a full-engine package or in groups. Complete kits are ideal for engine rebuild projects or safeguarding newly acquired assets. Our insulation cover groups enable deployment in stages, such as turbo and manifold implementation. Ordering in groups is ideal for replacing damaged blanket sections.

As listed below, we offer several blanket cover groups depending on engine configuration.

Heat-critical component blanket kits

- Manifold shielding

- Turbo lagging

- Turbo wastegate covers (dozers)

- Junction insulation

Proximity and radiant heat blanket kits

- Engine pipes and exhaust lagging

- Bellow covers

- Mufflers and tailpipe blankets

- Firewall shielding (excavators)

Specialist application blanket kits

- DPF insulation

- Sound suppression pipe lagging

- Dual-wall exhausts (turbo covers & manifold covers)

Monitoring and maintaining exhaust blankets

A thermal blanket, like car tyres, needs periodic inspection, adjustment, and replacement when excessively worn. We have created a scheduled maintenance checklist to help prevent engine fires and maximise blanket life. For an effective protective barrier, review blanket coverage and integrity on an ongoing basis.

Australian-made for your mining fleet

Do you need to consider a low-cost blanket protective measure to protect your multi-million dollar fleet? Our blankets are premium Australian-made products supported by our expertise in design and production. Depending on your fleet, we can stock essential blanket kits to reduce downtime.

EXHAUST BLANKET INSIGHTS

DOWNLOAD TECHNICAL INSIGHTS

Our Commitment

Our blanket dedication to excellence

Aletek is unwavering in its pursuit of excellence. Our blanket production processes are meticulously planned, from sourcing premium materials to expert sewing and assembly.

Product designs underpinned by R&D

Our latest thermal blankets incorporate lessons learned from testing. For instance, using a thinner coating can reduce burn potential. Thermal imaging has helped identify heat issues and improve designs between section overlaps.

CNC pattern production for consistency

Our blanket pattern cutting is automated with a CNC flatbed cutter. We believe it is the only one in the Southern Hemisphere. Our team of experienced sewers and finishers completes the production of thermal blankets.

A final wrap-up on blankets

From 3D scanning to CAD, our product design phase is well-defined. Controlled templates, lean workflows and quality checks inform our manufacturing process. An expert oversees design and templates to ensure continued excellence in our Thermal Division.

THERMAL BLANKETS

Subscribe

Is there a project you need help with?

Maybe you want to upgrade your fleet to reduce downtime. We’ve got dedicated Business Development Managers to help you meet your onsite goals. Get in touch to learn more and ask about our site-specific parts catalogues.

"*" indicates required fields