Aletek’s DPF upgrades for Atlas Copco and Epiroc utilise high-capacity filters to reduce emissions. Our DPFs will improve drills, mine trucks and scoop trams.

OEM DPF Filter Upgrades for Mining

We rely on superior, high-capacity diesel particulate filters to provide industry-leading DPM filtration for mining fleets. We specialise in equipping underground mines with high-performance, Australian-made DPF upgrades.

Installation assistance and tech support

DPF monitoring and data management

Emissions and on-site testing

DPF cleaning and lifecycle management

Direct-fit replacement DPF Filters

-

Improved air quality for underground mine workers

-

An emphasis on direct-fit OEM integration

-

Enhanced performance for less downtime

-

Our process ensures quality and durability

-

We extend operational life with our diesel exhaust filters

-

Savings on Total Cost of Ownership (TCO)

We build purpose-made DPFs for mining equipment that help mitigate power loss and backpressure problems. Our DPFs are housed in heavy-duty, durable enclosures built around the most advanced substrates available. For direct-fit installation, Aletek DPF upgrades integrate seamlessly with OEM exhaust configurations.

What makes Aletek mining DPF upgrades superior?

Our DPFs help solve industry problems

DPF (Diesel Particulate Filter) may be a dirty word underground, but it doesn’t have to be. We know filters inside and out. Aletek has designed, installed, and tested DPFs for nearly a decade. We solve common industry problems with our wall-flow DPFs:

- A safer underground with industry leading DPM reductions

- Direct-fit design for in-line installation (no hot works)

- Durable 304-grade stainless steel DPF housings

- Robust rock covers built with 6mm plate steel

- Superior filters minimise servicing with lower regen temps

- Benchmark performance without backpressure issues

Direct-fit DPFs from Aletek are better by design

Aletek DPF upgrades fit most OEM DPF mounting locations. Plate steel rock covers protect DPFs exposed outside the vehicle. Direct-fit replacement DPFs should meet the following criteria:

- Machine and engine specific DPF design

- Our DPF filters install in-line with OEM exhaust system

- Connects turbo to DPF to tailpipe with compatible pipes

- No hot work modifications (eg. welding or oxy cutting)

Our filters are industry leading

A best-in-class filter is at the heart of our DPFs. Aletek DPFs improve air quality and exhaust performance. Our superior design filters more, stores more soot, extends service life, and minimises performance issues.

- Trap >99% DPM with wall-flow DPFs (industry milestone)

- North American DPF filters with regenerative catalyst coating

- High-flow diesel particulate filters solve low power and backpressure

- Reduce cleaning costs and extend service life

- Protection in transit with rotable frames

Turn DPF pain into gain

High backpressure shortens service intervals

Don’t let substandard DPF performance affect your underground productivity. As a result of high backpressure, maintenance costs are higher and performance problems arise. Exhaust gas temperatures also increase the risk of turbo failure. Our team can assist in alleviating these frustrations.

Factors that impact TCO

Reducing TCO (Total Cost of Ownership) for underground maintenance crews is a priority. The following factors have a significant impact on TCO:

- Initial DPF purchase price

- Shorter service intervals – increased cleaning, costs, and downtime

- Lifecycle – durability and effectiveness (hours/years)

With an Aletek DPF, you can save 30-40% on TCO and extend the service life of your equipment. You can expect a product lifecycle of up to 20,000 hours with our DPFs.

Solutions for mining DPF filters

We provide DPF upgrades for OEMs such as Caterpillar, Epiroc, Normet, Sandvik, and Volvo. Solutions we offer include:

- Wall-flow DPFs – rotable frame and rock cover options

- Thermal blankets – lagging for DPFs and exhaust parts

- Partial DPFs – when machines can’t regenerate a wall-flow (duty cycle and temperature)

We produce reliable, high-performance DPFs with our in-house design and manufacturing teams. To make installation easier, our DPFs are direct-fit and OEM compatible. Advanced filter technology underpins our DPFs.

Why track DPF performance?

Having an Exhaust Backpressure Monitoring (EBM) system for your DPF is critical. EBMs record backpressure, exhaust gas temperature, and engine RPM. This data helps predict service lifecycles, schedule DPF cleaning, and analyse filter performance.

Monitoring exhaust performance has the following benefits:

- Provide predictive maintenance insights

- Reduce backpressure and unscheduled maintenance

- Lower ownership costs (TCO)

- Identify engine issues that affect DPF lifecycle

By providing real-time or semi-real-time data transfer, we can assist maintenance planners. Ask us about real-time data management through Wi-Fi connectivity.

High-speed EBM features

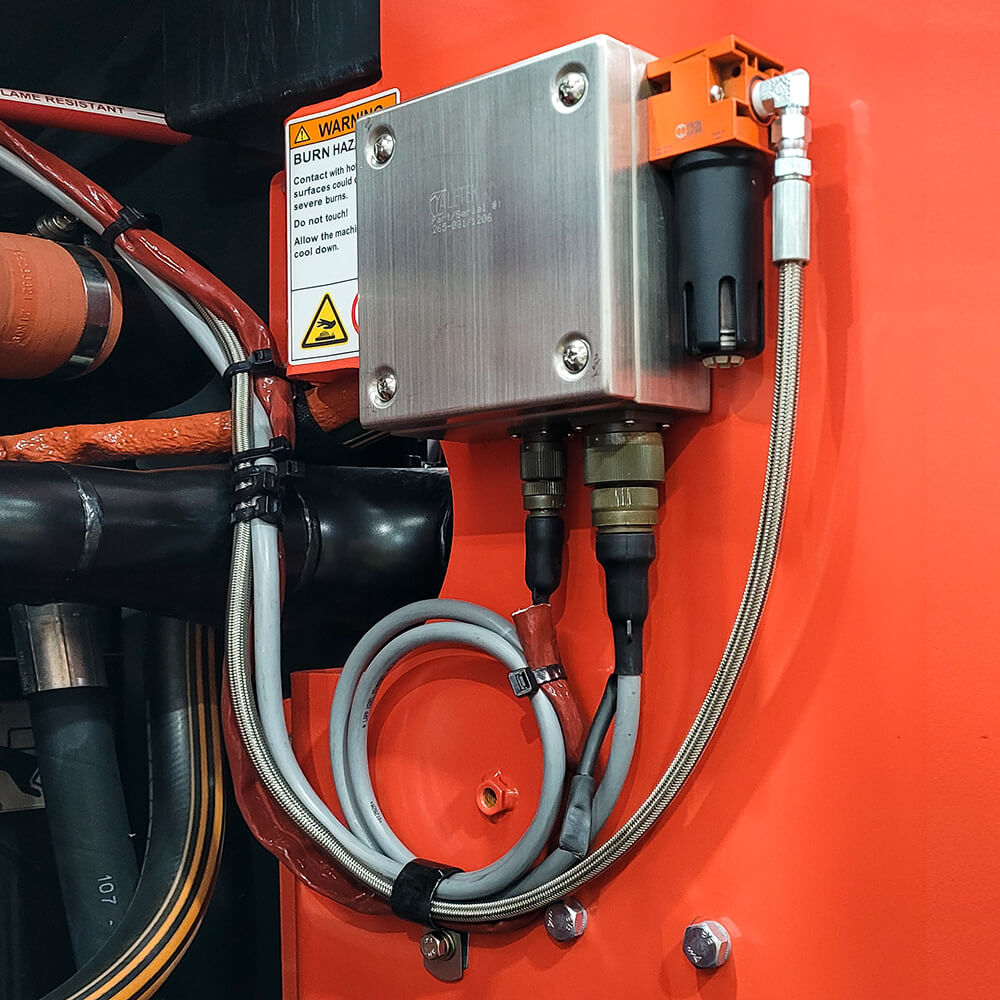

The Aletek EBM has evolved into a rugged, heavy-duty system with advanced technology.

- High-speed data transfer, most downloads under 2 minutes!

- Improved user-friendly interface

- Mounted inside an IP66, 316-grade stainless enclosure

- Thermocouple cable housed in silicone fire-rated sleeves

- Teflon hose with stainless braiding for backpressure (high-temp rated)

- Mine-spec rated plug-n-play harnesses

- Dash-mounted warning light

Our Commitment

Building a World-class DPF

Our team design and build world-class DPFs. We select the finest raw materials, fabricate flawlessly, and finish with skilled stainless steel pickling.

A meticulous design approach

One size doesn’t fit all. We align filter substrates with OEM engine specifications during the technical design phase. With the help of a leading filter supplier, we have developed the perfect substrate catalyst coating for machine duty cycles and temperatures.

We use controlled drawings and pipe jigs

A quality-control process ensures consistency at critical stages of the DPF builds. The fabrication process is guided by a drawing system managed by our design team. For direct-fit integration, pipe jigs are essential for replicating OEM exhaust paths.

Fabricating impeccable DPFs

Our fabrication process is highly accurate, relying on a lean manufacturing workflow and processes like laser cutting. We use stainless steel pickling to help prevent corrosion. Powder coating and ceramic coating finishes are also available.

DPF UPGRADES

Subscribe

Is there a project you need help with?

Maybe you want to upgrade your fleet to reduce downtime. We’ve got dedicated Business Development Managers to help you meet your onsite goals. Get in touch to learn more and ask about our site-specific parts catalogues.

"*" indicates required fields