We understand the importance of machine availability. Your KPIs suffer from unplanned downtime, early component failure, and restricted parts availability. As a result, Aletek has developed specialised OEM replacement products to resolve these problems.

Tailor-made Upgrades

Let us help you reduce downtime

Installation assistance

Expert technical support

Testing and reports

Exhaust-related fleet audits

Design criteria

- Ensure maximum worker safety with superior DPM filtration

- Eliminate performance issues and reactive maintenance

- Tailor DPFs to suit a specific asset and engine configuration

- Simplify installation with a preference for direct-fit integration

- Select materials and high-grade steels to enhance durability

- Maximise ROI by extending OEM reliability and lifecycle

- Availability of spare parts for critical assets

Material selection

To ensure consistent quality and best-in-class DPFs, we’re intentional about our supplier partnership selections.

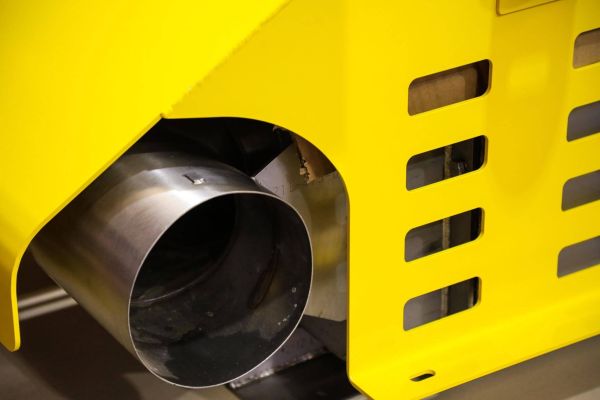

- Steel pipes & sheets – We use high-quality steel from an Australian supplier for our DPF housings, pipes, rotable frames and rock covers. For precise pipe bends, we procure steel donuts.

- Substrates – A leading filter provider has exclusively partnered with us. These substrates feature a high-grade regenerative catalyst coating.

- Surface finishing – To prevent corrosion, we use stainless steel pickling. Other surface finishes are available, including powder coating and ceramic coating.

- DPF fittings – We source premium components such as wiring harnesses, V-band clamps and installation hardware.

- Data loggers – Data logger enclosures are IP66-rated with 316-grade stainless steel. Fire-rated sleeves protect cables, and hoses are high-temperature rated.

Product design

R&D improvements

- Before design begins, define a concise project outline

- Backpressure testing and engine data collection

- Input from clients, including service intervals

- Consider an OEM engineering analysis including FEA and CFD

Design Team process

- Designs led by 3D scans, onsite measurements, and OEM DPFs

- 3D printing, CAD design, and prototyping managed in-house

- Conduct field trials when necessary to collect data

- Physical pipe jigs built to match OEM pipes as required

- Emission Control Product Manager approves designs

Project management and onsite support

- Custom project management and implementation options

- Site-specific parts catalogues, training and user guides available

- Onsite support services, emission testing, and DPF fleet audits

- Remote and onsite data monitoring

DPF system manufacturing

Lean manufacturing and quality assurance ensure accurate and exceptional fabrication. We use the latest technology in our modern workshop.

- Raw components collected from the warehouse

- Preparation stage with laser cutting, punching, and folding conducted in-house

- Processing stage includes rolling laser-cut sheets, cutting pipe lengths, and shaping donuts to specific angles

- Welding preparation involves drilling, pressing, and expanding

- Templates, pipe jigs, and multiple QA checks assist fabrication

- Welding and cleanup activities commence, and filter substrates added

- The last QA stage inspects fabrication, welds, and fit-out for accuracy

- Surface pickling removes imperfections from DPF enclosures

The same process applies to rock covers and rotable frames, except for a powder-coated finish.

Continuous improvement loop

- We resolve technical issues, including installation problems

- Long-term solutions over short-term fixes (e.g. root cause analysis)

- Use customer feedback to help refine product designs

Subscribe

Is there a project you need help with?

Maybe you want to upgrade your fleet to reduce downtime. We’ve got dedicated Business Development Managers to help you meet your onsite goals. Get in touch to learn more and ask about our site-specific parts catalogues.

"*" indicates required fields